Powder metallurgy - Wikipedia

Any fusible material can be atomized. Several techniques have been developed which permit large production rates of powdered particles, often with considerable control over the size ranges of the final grain population. Powders may be prepared by crushing, grinding, chemical reactions, or electrolytic deposition. The most commonly used powders are copper-base and iron-base materials.

Metal powders in additive manufacturing: A review on

2021年7月1日 The current review gives insight into different metal powder manufacturing methods, the essential properties of metal AM powders, how the AM process can

An introduction to metal powders for Additive

2018年6月1日 As the Additive Manufacturing industry grows, so does the number of metal powder suppliers and the range of different powder types that are available. In the following article Toby Tingskog presents a

Metal Powders World Class Metal Powder Manufacturer

AMETEK SMP Eighty Four » PRODUCTS » Metal Powders Metal Powders Our metallurgists specialize in the design, development and production of specialty metal

GKN Powder Metallurgy A Metal Solutions Provider

GKN Sinter Metals. The world's leading manufacturer of precision powder metal products, sintered structural parts, porous products and filters, sub assemblies, soft magnetic

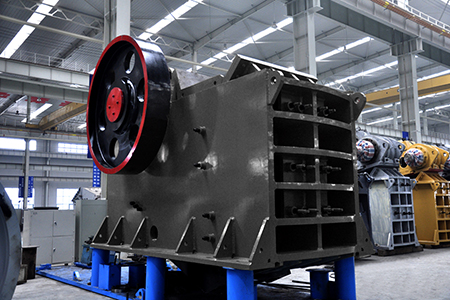

Making Metal Powder - MPIF

The first step in the overall powder metallurgy (PM) process is making metal powders. There are four main processes used in powder production: solid-state reduction, atomization, electrolysis, and chemical. Solid-State